GRP Steel Core

Our “high strength” GRP with a 0,50mm steel wire core and outer diameter up to 3,00mm => monthly capacity 3 000km

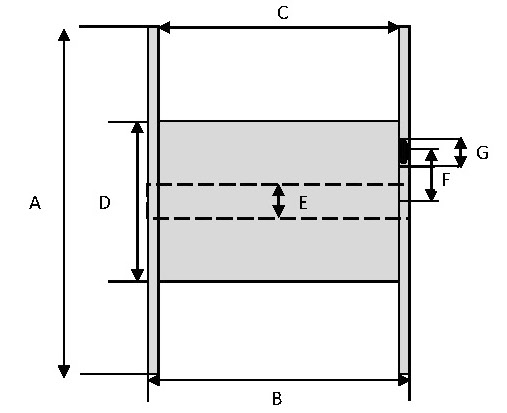

Steel Wire 0,5mm inserted GRP A mm Characteristics

| ITEM | UNIT | SPECIFICATION | TEST METHOD |

|---|---|---|---|

| Appearance | Shall be Good | Good | – |

| Diameter Tolerance | mm | A ± 0.06 | Micrometer |

| Specific Gravity | g/mm2 | 2.0 ~ 2.2 | ASTM D 792 |

| Tensile Strength | Kg/mm2 | Min. 130 | ASTM D 3916 |

| Tensile Modulus | Kg/mm2 | Min. 5000 | ASTM D 3916 |

| Elongation at Break | % | Min 2.5 | ASTM D 3916 |

| Load at 0.5 Elongation | N | Min. 990 | ASTM D 790 |

| Load at 1.0 Elongation | N | Min. 1980 | ASTM D 790 |

| Coef. of Thermal Expansion | /℃ | Nom. 6*10-6 | – |

| Minimum Bending Radius | mm | 50 X Dia | 80°C x 24h |

| Glass Content | % | Min. 67 | – |